Rapid prototyping can be achieved in multiple ways, and each has their advantages and disadvantages. Working with EKS Designs will help by balancing customer needs with price considerations. Additive manufacturing (often 3d printing), machining (lathe, mill), casting, molding, forming, joining, and working with existing hardware should all be taken into account.

Traditional methods such as machining, casting, molding, forming, and joining are great for simple, medium to large production runs, medium lead times, where strength, endurance, and precision are needed.

Additive manufacturing is great for complicated designs that need to be customized or made in small runs. They also have a much shorter lead time which allows for faster iterations of designs. They do have high costs for large runs though, have limited strength/endurance, and are not as precise. Within the umbrella of additive manufacturing there is a lot of variation though.

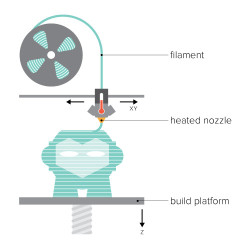

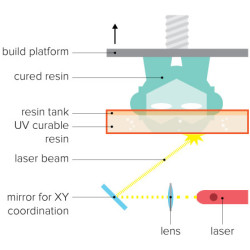

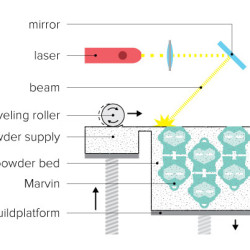

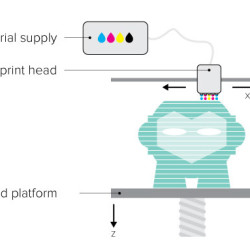

The most common 3d printing techniques are fused deposition modeling (FDM), stereolithography and digital light processing (SLA & DLP), selective laser sintering (SLS), material jetting (PolyJet and MultiJet Modeling), and metal printing (Selective Laser Melting and Electron Beam Melting).

FDM is the cheapest and can be strong and functional. It is not the most accurate though. Supports are often needed.

SLA is great for highly accurate parts with smooth surfaces. It is frequently used for small detailed parts. Large objects are often too expensive though. Supports are needed.

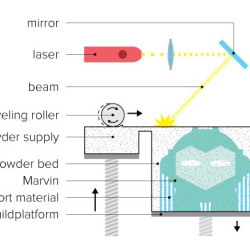

SLS allows for complete design freedom and complex mechanisms but is also expensive and has longer lead times. No supports are ever needed.

Material jetting is the best if you need to have multiple materials mixed in one part. It also is one of the most precise 3d printing technologies today. Support is needed but leaves no surface blemishes.

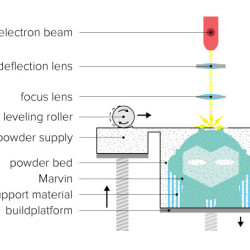

Metal printing (EBM and DMLS) allows for complex designs to be made rapidly, and even allows for previously impossible creations. It is the most expensive 3d printing technology but allows for very strong final products. Supports are required and additional machining work is often needed to clean up or bring parts into tolerance.

If you have any other questions, please use the contact page. Feel free to ask questions about the model or ask for advice on 3d printing.

Things to consider before sending an order:

- Cost is per volume, so an increase in scale increases cost exponentially. If scale is not important this is something to keep in mind to save on your print.

- The best prints are those that require no support. If support is needed, it can be removed for an additional fee but the quality will not be as high.

- Double check your model before sending it in, especially for dimensional accuracy.